Material 17 4 PH

ANY SIZE – ANY TIME

Your specialist for 17-4 ph sawn steel from forged billets directly from stock in Texas. We provide metal cutting services.

Introducing 17 4PH steel – the epitome of strength, durability, and versatility. This exceptional steel alloy is renowned for its outstanding combination of high strength, corrosion resistance, and excellent mechanical properties. Material 17 4 ph stainless steel material is characterized by high yield strength, good corrosion resistance, strength, thermal conductivity, very good dimensional stability and high wear resistance. 174 PH is one of the most important age-hardenable Cr – Ni – Cu steels. Low temperature service is possible by intercalation with Condition A, 17 4 H900, 17 4 H1100, 17 4 H1150 and 17 4 H1025. Excellent notched impact strength is also provided at sub-zero temperatures. The good mechanical properties and corrosion resistance make the material suitable for use in marine environments, but is susceptible to crevice corrosion in stagnant seawater.

Whether you’re in the automotive, or manufacturing industry, 17-4 stainless steel is your ultimate solution. Its unique composition, including chromium, nickel, and copper, provides exceptional resistance to various corrosive environments, making it ideal for applications where durability is paramount.

But that’s not all! Material 17 4 also offers remarkable machinability, allowing for easy fabrication and precision machining. Its heat treatable nature enables you to achieve a wide range of mechanical properties, tailoring it to meet your specific requirements. SS steel high pressure pumps for oil and gas industry.

With stainless steel alloy 17 4 PH, you can trust in its exceptional performance and reliability. Its high strength-to-weight ratio makes it perfect for weight-sensitive applications, while its resistance to stress corrosion cracking ensures long-lasting performance even in demanding conditions.

Don’t compromise on quality and durability. Choose Alloy 17 4PH steel for your next project and experience the difference it can make. Contact us today to learn more about this remarkable steel alloy and how it can elevate your products to new heights.

Available in swap state:

Condition H1150 (Rm > 930N/mm2)

Condition H1025 (Rm > 1070N/mm2)

Condition H900 (Rm > 1310N/mm2)

Condition A (Rm max. 1200N/mm2) max. hardness of 363 HB.

International identifiers for steel 17 4 PH:

AISI 630, ASTM A564-89 17-4 PH, JIS SCS24 / SUS630, AFNOR Z7CNU15-05 / Z7CNU17-04

Applications:

Due to good mechanical properties and corrosion resistance, the material is suitable for use in marine environments, but is susceptible to crevice corrosion in stagnant seawater.

17-4 PH is classified under AISI 630.

The material 17-4 PH is used in plant construction, the chemical industry, the woodworking industry, offshore, shipbuilding, mechanical engineering, the oil industry, the paper industry, the sports and leisure industry and as a cast variant (ESR) in air and aerospace.

Properties:

| malleability: | good |

| weldability: | good |

| mechanical properties: | excellent |

| corrosion resistance: | good |

| machinability: | bad to medium |

The special properties of the 17-4 PH material are its suitability for low temperatures and its usability up to approx. 315°C.

Forging of AISI 174 PH: Forging of 17 4 stainless steel takes place in a temperature range from 1180°C to 950°C. Cooling to room temperature takes place in air.

Steel 17 4PH: Welding: Optimum welding conditions are required for welding. The condition of the base material must be taken into account, as copper is present in stable form. This does not promote hot cracking. To prevent stress cracking, the material must be subjected to solution annealing again within a very short time after welding, followed by aging.

Corrosion resistance of stainless steel 17 4PH: 17-4 stainless steel is suitable for use in marine environments. This stainless steel has very good mechanical properties and corrosion resistance. Additional protection is required against crevice corrosion caused by standing seawater.

Machining of material 17-4 PH: 17-4 PH material is machinable in the age-hardened and solution-annealed condition. Depending on the hardness, the machinability varies depending on the condition.

Heat treatment

between the temperature of 1020°C and 1050°C the 17-4 PH material should be sprayed out of solution. This is followed by quenching in water, oil or air. This depends on the cross section of the component.

To ensure the complete transformation of an austenite to a martensite, the material must be able to cool to room temperature.

physical properties:

| density in kg/cm³ | 7,8 |

| electrical resistance at 20°C in (Ω mm²)m | 0,71 |

| thermal conductivity at 20°C in W/(m K) | 16 |

| specific heat capacity at 20°C in J/(kgK) | 500 |

| magnetizability | available |

Chemical analysis:

| 17-4 PH | C | Si | Mn | P | S | Cr | Mo | Ni | V |

| min. | 15 | 3 | |||||||

| max. | 0,07 | 0,7 | 1,0 | 0,04 | 0,03 | 17,50 | 0,6 | 5 |

| 17-4 PH | Al | Cu | N | Nb | Ti |

| min. | 3,0 | 5xC | |||

| max. | 5,0 | 0,45 |

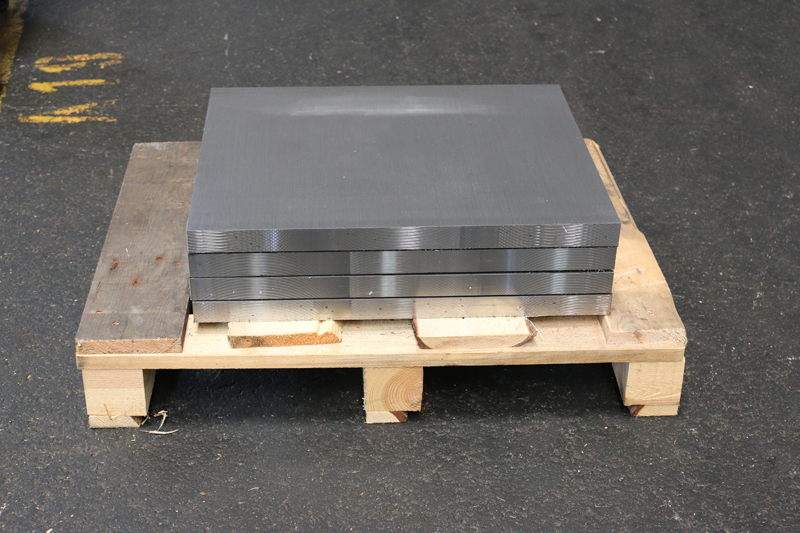

17 4 Ph from stock:

flat, forged, solution annealed and annealed tempered

Benefits of sawn cuts:

Due to mechanical processing with the saw, the material structure shows much lower unintentional deformation and material hardening than, for example, oxyfuel cutting. Therefore, the already machined piece from the saw has a homogeneous structure at the edge, which remains unchanged in the further processing of the material. This circumstance allows for immediate finishing work with milling or drilling of the piece, without the need for additional annealing or similar processes.

Produced to highest standards

Quick delivery

From stock in Texas

Specialist for sawn steel blocks directly from stock USA

Contact person

Karol Borycki

Popular steel:

Important questions

What is 17-4 PH stainless steel standard?

The standard for 17-4 PH stainless steel is typically ASTM A693.

What is the ASTM equivalent of 17-4 PH?

The ASTM equivalent grade for 17 4PH is ASTM A564 Type 630.

How hard is 17-4 PH stainless steel?

The hardness of 17 4 stainless steel can vary depending on the heat treatment and aging process it undergoes. Typically, it can achieve a hardness range of approximately 35-45 HRC (Rockwell C scale) after heat treatment.

What phases are in 17 4 PH steel?

174 PH primarily consists of a martensitic phase (alpha prime) and a precipitation-hardening phase (delta or gamma prime) formed during aging heat treatments. These phases contribute to the material’s strength and hardness.

Is 17-4 PH stainless steel magnetic?

17 4 material is generally magnetic in all conditions due to its martensitic structure. However, its magnetic properties can be affected by factors such as heat treatment and aging processes.