AISI 420 SS

ANY SIZE – ANY TIME

Your specialist for AISI 420SS from forged billets directly from stock in Texas.

We provide metal cutting services.

SS 420 is a martensitic, corrosion- and acid-resistant chromium steel that is supplied in a hardened and tempered condition. This steel is easy to polish, has low distortion and is through-hardenable with a high hardness acceptance. AISI 420 SS has very good mechanical properties in terms of polishability, chemical resistance, forgeability and medium weldability.

International identifiers

SS2314, 4H13, 1.4021

Applications:

SS 420 is used in the food industry as it can be used with chemically aggressive and acid-absorbing plastics such as thermosets and thermoplastics, PVC aminoplastics, plastic injection moulded parts and machine parts.

Weldability:

| Welding: | conditionally possible |

| Machinability: | 5 (1 = bad – 10 = good) |

| Polishing: | yes |

| Chorosion class: | 1 (0 = weak – 5 = good) |

bonus QT700 / QT800

Chemical analysis:

| AISI 420 420 SS |

C | Si | Mn | P | S | Cr | Mo | Ni | V |

| min. | 0,36 | 12,,5 | |||||||

| max. | 0,42 | 1,00 | 1,00 | 0,03 | 0,03 | 14,5 |

Physical Properties:

| Density in kg/dm3 | 7,80 |

| Young’s modulus (103 MPa) | 200 |

| Thermal conductivity at 20°C in W/(m K) | 17,0 |

| Specific heat capacity at 20°C in J/(kg K) | 460 |

Processing:

Polishing: Polishing of SS 420 is possible in the soft annealed and hardened condition. Good surface preparation is essential for a good polish.

Etching: Good photoetchability is given. (grain)

EDM: AISI 420 can be eroded in hardened and tempered condition. It must then be stress-relieved again to approx. 20°C below the last tempering temperature.

Nitriding and hard chrome plating are not common for this material.

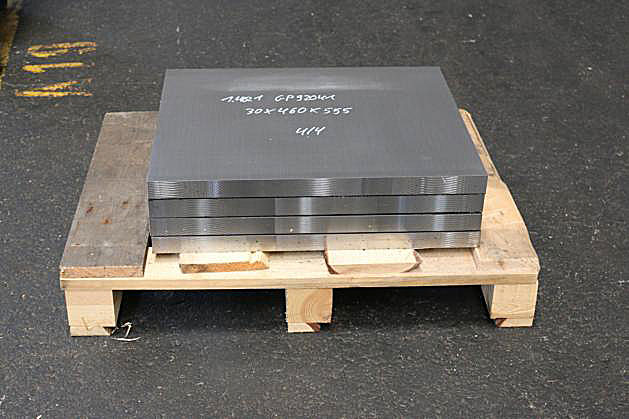

Benefits of sawn cuts:

Due to the mechanical processing with the saw, the structure of the material shows much less unintentional deformation and material hardening than, for example, oxyfuel cutting.

Therefore, the workpiece already machined by the saw has a homogeneous structure at the edge, which does not change in the material continuation.

This circumstance allows the workpiece to be finished immediately by milling or drilling, there is no need for soft annealing or similar.

We deliver directly from stock:

Flat, forged, quenched and tempered

Produced to highest standards

Quick delivery

From stock in Texas

Specialist for sawn steel blocks directly from stock USA

Contact person

Karol Borycki

Popular steel:

Important questions

What is AISI 420?

AISI 420, also known as X20Cr13 is a martensitic stainless steel grade known for its high carbon content (around 0.15% to 0.40%) and moderate corrosion resistance. It is often used in applications requiring high strength, hardness, and wear resistance, such as surgical instruments and cutting tools.

What is special about X20Cr13 ?

X20Cr13 is a specific grade of stainless steel, known for its composition of 0.20% carbon and approximately 13% chromium. It is commonly used in applications where moderate corrosion resistance and good mechanical properties are required.

Is AISI 420 stainless steel?

It falls under the martensitic stainless steel category, which is known for its high strength, hardness, and wear resistance.

Is AISI 420 SS magnetic?

X20Cr13 is magnetic. Martensitic stainless steels like X20Cr13 are generally magnetic due to their microstructure, which consists of martensite, a magnetic phase.

Can you harden SS 420?

You can harden 1.4021 through heat treatment processes such as quenching and tempering. Hardenability is one of the key characteristics of martensitic stainless steels like

What can cause AISI420 SS to rust?

The material can rust when exposed to conditions that promote corrosion, such as moisture and corrosive chemicals. However, its corrosion resistance is relatively lower compared to austenitic stainless steels.