SS 347 / AISI 347

AISI 347 is a stainless, austenitic chromium-nickel stainless steel alloyed with niobium. Due to the carbide former niobium, the material is resistant to intergranular corrosion in the welded condition, irrespective of thickness and cross-section.

We supply the material as sawn steel blanks directly from stock. Compared to round or square bars, our rectangle bars SS 347 offer unique advantages in specific applications

The SS 347 has excellent weldability, this is a common characteristic from austenitic steels, as well as high mechanical properties, which guarantees good ductability, and it is recommended for some cold forming processes.

The application areas of grade SS 347 is normally in corrosive environments and high temperatures. It is currently being used in the manufacture of collector rings for aircrafts, engine components for rockets, exhaust manifold for cars, expansion joints and equipment for chemical processing at high temperatures.

International identifiers of ss 347 steel:

S34700, SS2338, 0H18N12Nb, 1.4550

Applications of steel 347:

In nuclear power plant construction, the stainless material steel 347 ss has established itself through its high corrosion resistance. In the private sector, it is used for household appliances. The material is also often used in the film and photographic industries.

In the chemical and food industries, the material grade AISI 347 ss is often used for tanks and apparatus.

Properties of 347 stainless steel:

| welding qualification | good |

| Corrosion resistance | very good |

| Polishability | only conditionally possible |

| Machinability | only possible to a limited extent |

Welding: The material 347 ss is suitable for welding with all common welding methods. No special measures or post-weld heat treatments are required.

Corrosion resistance: Good resistance to a wide range of environments in the chemical, textile, oil refining, dairy and food industries.

Hot forming: Hot forming should be carried out between 1120°C – 1020°C. This is followed by cooling in air or water.

Processing:

| Cold forming | is possible |

| Machining processing | only possible to a limited extent |

| Polishability | unsuitable |

Physical Properties SS347:

| Density in kg/dm3 | 7,9 |

| Electr. Resistance at 20°C (Ω mm2 /m) | 0,73 |

| Thermal conductivity at 20°C in W/(m K) | 15 |

| Specific heat capacity at 20°C (J/kg K) | 500 |

Chemical analysis of ss 347 steel:

| SS 347 | C | Mn | Si | Cr | Ni | P | S | N | Nb |

|---|---|---|---|---|---|---|---|---|---|

| min. | 0,04 | 2,00 | 0,75 | 17,0 | 9,00 | 0,045 | 0,03 | 0,02 | 10xC |

| max. | 0,08 | 19,0 | 13,0 | 1,00 |

347 stainless steel:

Flat, forged, solution annealed and quenched, pre-machined

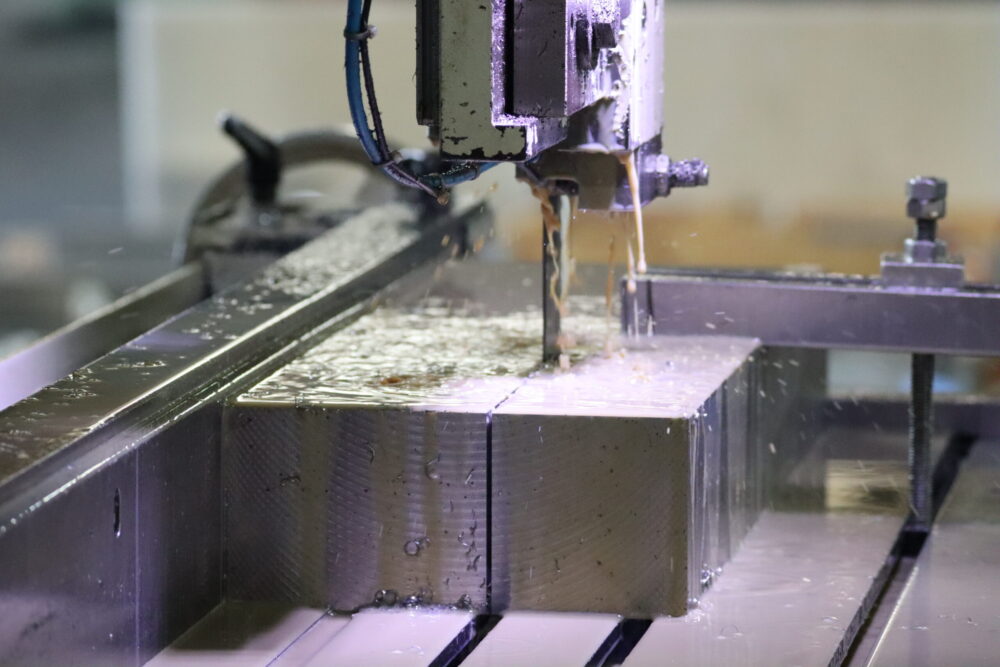

Advantages of saw cut of ss 347 steel:

The use of a saw for processing involves mechanical manipulation of the material, resulting in a reduced risk of unintended deformation and increased hardness compared to thermal cutting methods. As a result, the workpiece maintains a consistent structure, allowing for seamless continuation of material processing. This characteristic enables immediate finishing touches through milling or drilling without the need for pre-annealing or similar procedures.

Produced to highest standards

Quick delivery

From stock in Europe

Popular steel: