Nitronic® 50 stainless steel / XM 19

ANY SIZE – ANY TIME

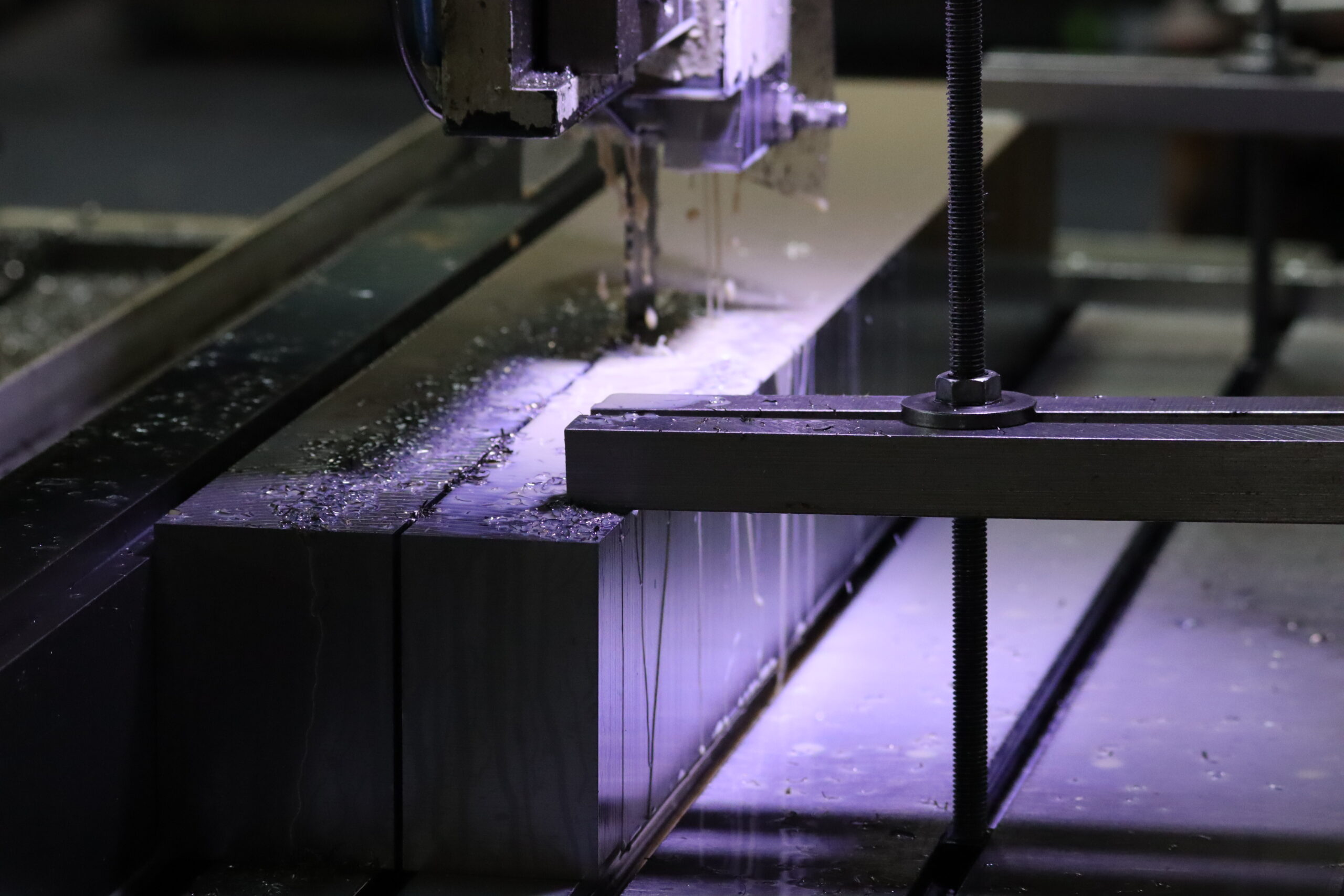

Your specialist for sawn steel from forged billets. We provide metal cutting services.

Rectangle bar XM-19 similar to (Nitronic® 50) is a non-magnetisable austenitic stainless steel. We also see it as a modified alloy of a modified 1.3964 in its field of application with an acceptable cost potential. The ESR remelting process gives it a particularly high degree of purity, and the long-term properties of the mechanical values are of course optimally guaranteed (keywords: lower S and P content). It differs from the usual 1.3964 due to the lower nickel and molybdenum content, but has better resistance due to the addition of vanadium.

International identifiers of Nitronic 50:

SEW 390, UNS S20910, ASTM A276, A479, AISI XM-19, Nitronic® 50

Applications of XM 19 material:

The XM-19 material, commercially known as Nitronic® 50, is a non-magnetic austenitic stainless steel. It is considered a distinct alloy and a modified version of 1.3964, offering a potentially acceptable cost for various applications. Thanks to the ESU remelting process, this material achieves a particularly high degree of purity, optimally guaranteeing its long-term mechanical properties, notably due to its low sulfur (S) and phosphorus (P) contents.

Although perioperatively it does not differ substantially from 1.3964, XM-19 has a lower nickel content. However, the addition of vanadium and molybdenum enhances its strength, making this material a superior choice for certain applications.

Application Sectors

The primary application areas for this ultra-clean material include the maritime sector, where it is used in drilling accessories, fishing tools, and non-magnetic mud pump motors. Additionally, due to its alloyed components of nickel, molybdenum, and vanadium, Nitronic® 50 steel is suitable for applications in the food and medical industries. It is also highly valued in the beverage production industry and in the manufacturing of household appliances.

In summary, XM-19 (Nitronic® 50) is a versatile, high-purity material ideal for a wide range of industrial applications requiring exceptional strength and durability.

Nitronic 50 Properties:

| Weldability | good without PWHT |

| Machinability | 4 (1 = bad – 10 = good) |

| Corrosion resistance | excellent |

| Forgeability | medium |

| Mechanical properties | good |

Material XM-19 (Nitronic® 50) is a non-magnetizable austenitic stainless steel.

heat treatment:

| temperature in °C | cooling | |

| hot forming | 1.150-950 | air |

| thermal treatment | ||

| Desolventizing annealing (+AT) | 1080-1030 | air, water (rapid cooling) |

Welding: XM-19 (Nitronic® 50) steel is weldable by commonly used methods, recommended filler metals 1.3954 and 1.3984. The max. interpass temperature should remain below 200°C and downstream heat treatment (PWHT) depends on the geometries.

Forging: Prior to forging, the steel should be heated to 1150°C and 950°C. The forging process is carried out at 1100°C to 900°C followed by rapid air or water cooling. Surface post-treatment by pickling is advisable.

Cold forming: Due to the high strain hardening, higher forming forces are required. Note the slight increase in permeability!

Corrosion resistance: Corrosion resistance is increased compared to conventional chromium-nickel-molybdenum steel and resistance to intergranular corrosion and stress corrosion cracking is given. It can also be pointed out that this steel is resistant to sea water at temperatures up to 40°C.

Machining: Machining is somewhat more difficult (work hardening) than with the bulk steel grades due to the high alloy content with greater time required. High-quality high-speed steel or carbide should be used here. The feed rate for turning is specified as less than 0.5 mm/rev at cutting speeds of 110 to 150 m/min.

Processing:

| Clasping processing | possible with caution (high-alloyed!) |

| Open die and closed die forging | is possible |

| Cold diving | is possible |

| Cold forming | is possible |

| Machining | no |

Special properties:

- Can be used in the temperature range up to 350°C

- non-magnetizable material (μr < 1,04)

- No pronounced steep drop in notched bar impact values at lower temperatures

Physical properties:

| Density (kg/dm3 ) | 7,91 |

| Electr. resistance at 20°C (Ω mm2 /m) | 14 |

| Thermal conductivity at 20°C (W/m K) | 0,70 |

| Spec. heat capacity at 20°C (J/kg K) | 460 |

Characteristics

Mechanical properties at room temperature: up to 203 mm

| Rp0,2 | A | Rp1,0 | KV |

| N/mm² | % | N/mm² | J |

| ≥ 365 | ≥ 35 | ≥ | ≥ 85 |

| Up to 203 mm thickness | |

| Tensile strength Rm | 690 – 950 N/mm2 |

| Brinell hardness | Max. 293 HBW |

Chemical composition of XM 19 material:

| XM-19 Nitronic® 50 |

C | Si | Mn | P | S | Cr | Mo | Ni | V | Cu | N | Nb |

| min. | 4,00 | 20,5 | 1,5 | 11,5 | 0,10 | 0,20 | ||||||

| max. | 0,030 | 0,75 | 6,00 | 0,025 | 0,010 | 23,5 | 3,0 | 13,5 | 0,30 | 0,30 | 0,40 | 0,25 |

XM19:

Flat steel, ESR melting technology; forging, solution annealing/annealing/tempering

Produced to highest standards

Quick delivery

From stock in Europe