1.4923 stainless steel / x22crmov12 1

ANY SIZE – ANY TIME

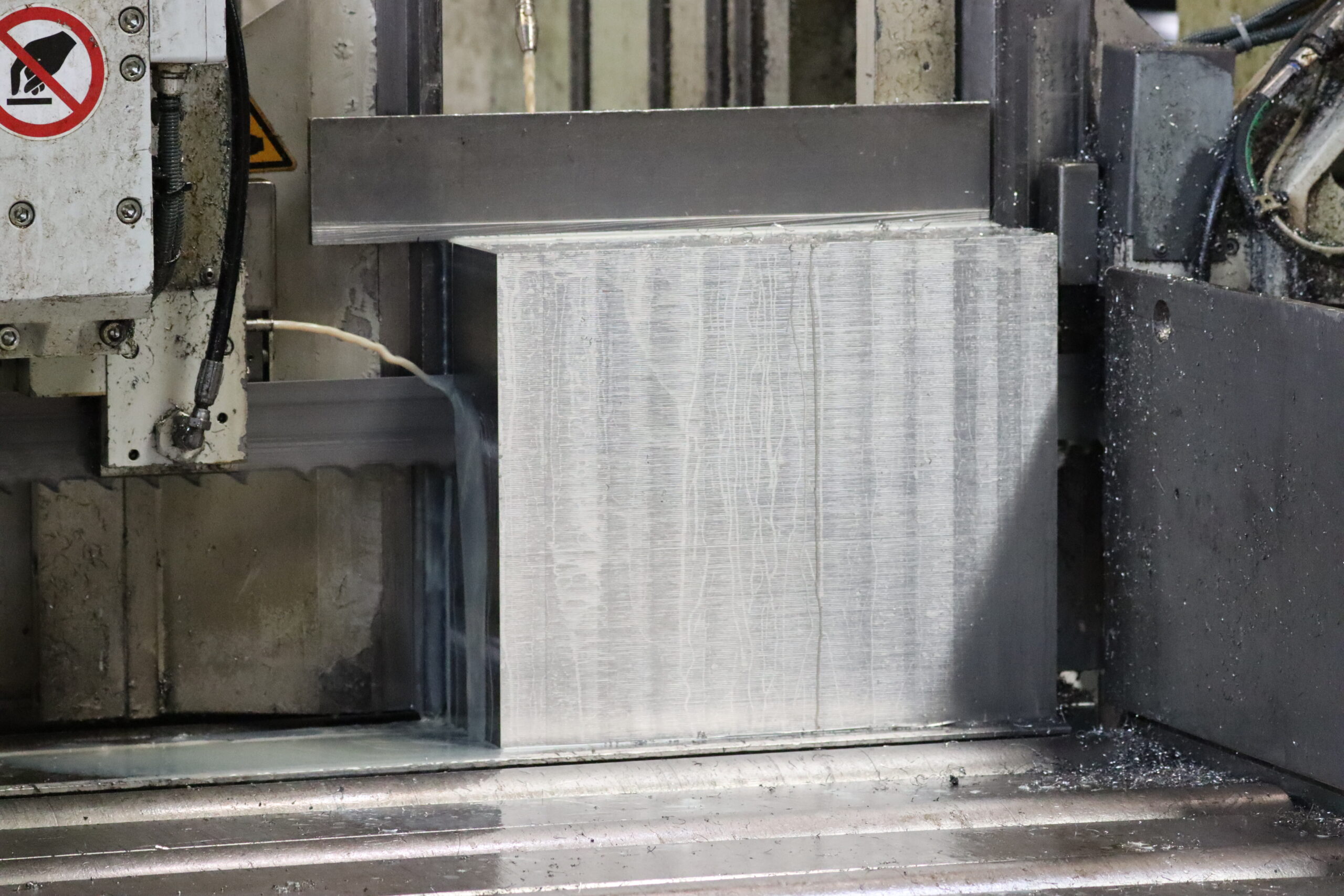

Your specialist for 1.4923 sawn steel from forged billets. We provide metal cutting services.

Rectangle bar 1.4923 is a tempered stainless, high-temperature chromium steel with molybdenum addition, which is used as a standard steel for components in steam turbines and high-temperature bolts. The vanadium addition increases the creep and creep rupture strength. Scale resistance up to approx. 600°C is given.

Overview of the most important steel of 1.4923 steel:

23H12MNF

Applications of 1.4923 stainless steel:

The material 1.4923 is mainly used in turbine construction, aerospace, reactor technology and for pressure and steam boilers.

Characteristics of 1.4923 steel:

| Forgeability | good |

| Weldability | good |

| Mechanical properties | good |

| Corrosion resistance | medium |

| Machinability |

medium |

Forging:

Forging takes place between 1180°C and 950°C, after the material has been slowly heated to 1150°C – 1180°C. This is followed by slow cooling in dry ashes, furnace or similar materials. After that, heat treatment can be carried out.

Welding:

Material 1.4923 can only be welded under certain precautions. A preheating temperature of 400°C – 450°C and an interpass temperature of 400°C – 500°C is optimal. After welding, the material can be directly quenched and tempered or soft annealed.

If a tempering treatment of the material 1.4923 is to be carried out, the welded joint must be cooled to 100°C -150°C. A tempering annealing of at least 4 hours is performed after complete martensite transformation at 740°C – 780°C. After this, slow cooling must be carried out.

Corrosion resistance:

This is limited due to the relatively low chromium content in natural environmental media. However, corrosion resistance is satisfactory in the absence of salt and chlorine concentrations. The material 1.4923 is resistant to water vapor.

Machining:

This depends on the strength and hardness. For the material 1.4923, the following cutting condition with coated carbide cutting tools can be suggested depending on different microstructural formations:

| Depth of cut (mm) | 6 | 3 | 1 | |

| Feed rate (mm/U) | 0,5 | 0,4 | 0,2 | |

| Annealed, Rm 700-800 N/mm2 | Cutting speed (m/min) | 100 | 130 | 165 |

Heat treatment:

Optimum mechanical properties are achieved by quenching and tempering the material 1.4923. The tempering temperature in the temperature range 640°C – 740°C and the subsequent cooling in air depend on the desired strength.

Processing:

| Cold forming | only possible to a limited extent |

| Chip forming | processing is possible |

| Cold upsetting | only possible to a limited extent |

| Open die and closed die | forging is possible |

Physical properties:

| Density (kg/dm3) | 7.70 |

| Electrical resistance at 20°C (Ω mm2/m) | 0.60 |

| Magnetizability | is present |

| Thermal conductivity at 20°C (W/m K) | 24 |

| Thermal conductivity at 650°C (W/m K) | 29 |

| Spec. heat capacity at 20°C (J/kg K) | 460 |

| Spec. heat capacity at 800°C (J/kg K) | 540 |

Chemical composition of x22crmov12 1:

| 1.4923 X22CrMoV12-1 |

C | Si | Mn | P | S | Cr | Mo | Ni | V |

| min. | 0,18 | 11,0 | 0,80 | 0,3 | 0,25 | ||||

| max. | 0,24 | 0,50 | 0,90 | 0,025 | 0,015 | 12,50 | 1,20 | 0,8 | 0,35 |

1.4923:

flat, forged

Produced to highest standards

Quick delivery

From stock in Europe

Popular steel: