15-5 PH XM 12

ANY SIZE – ANY TIME

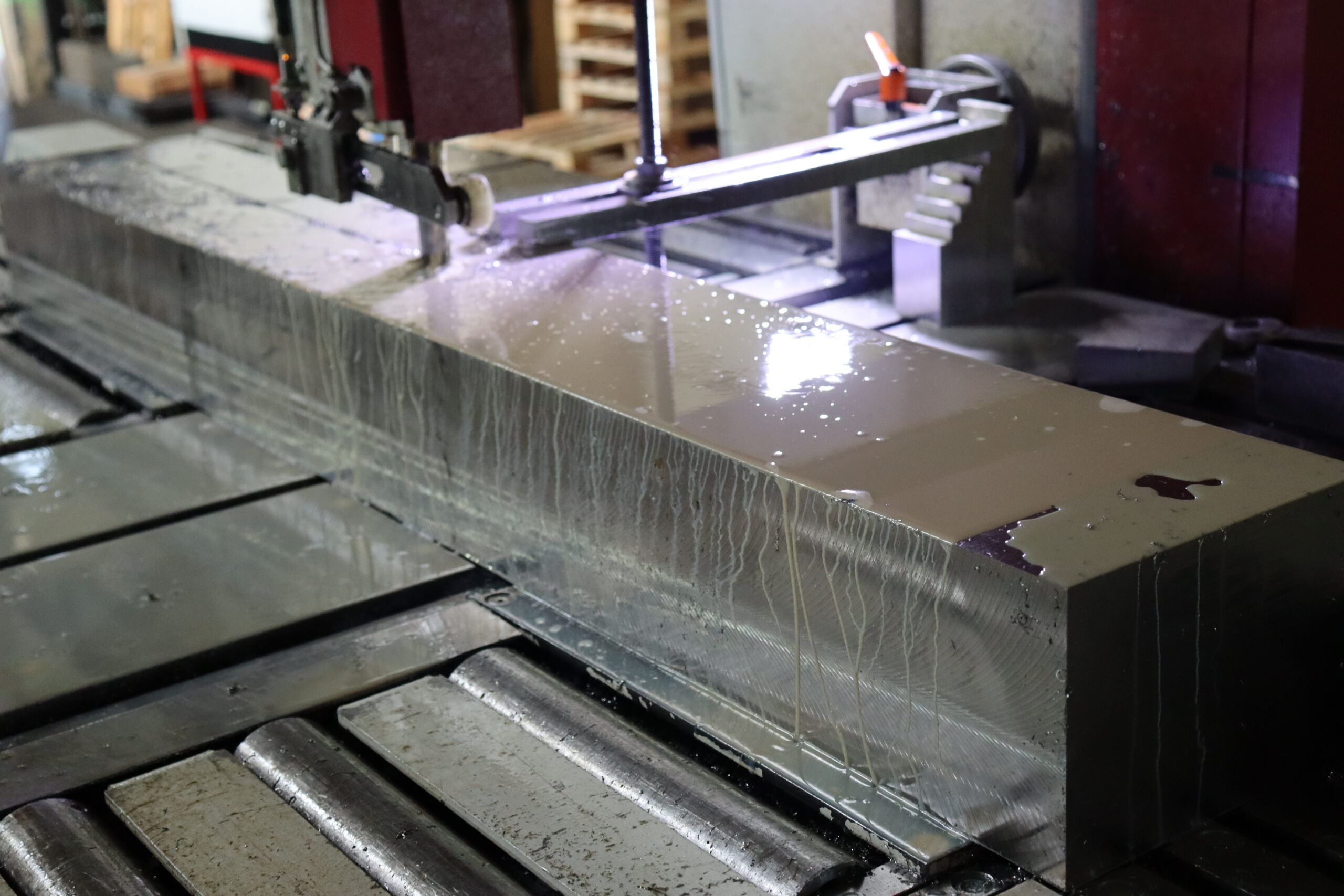

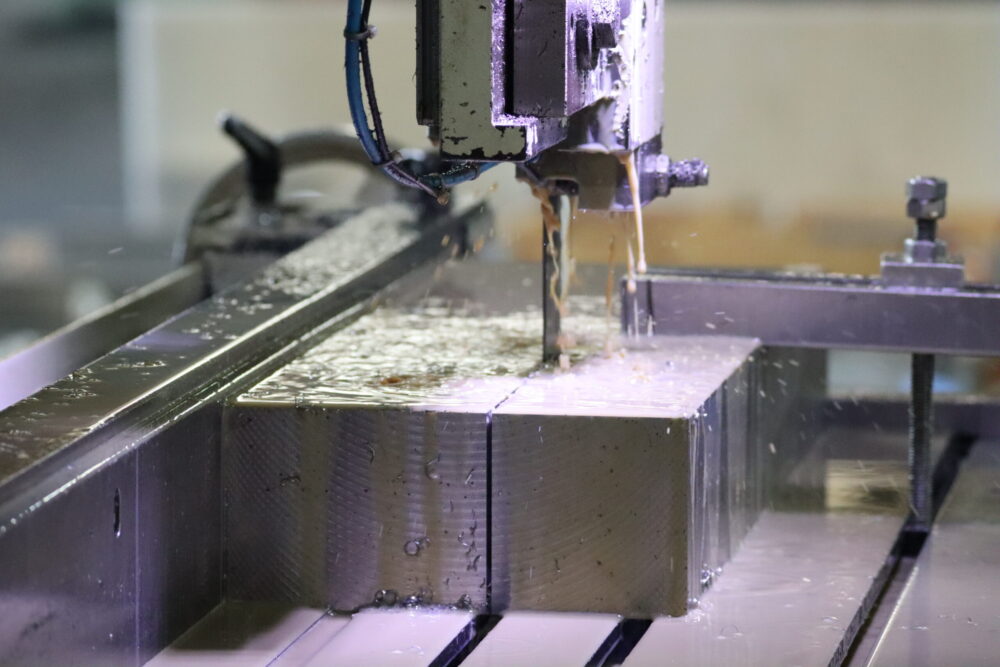

Your specialist for SS 15 5 PH XM-12 sawn steel from forged billets. We provide metal cutting services.

Introducing 15 5PH steel – a testament to strength, durability, and adaptability. Celebrated for its impressive amalgamation of high strength, corrosion resistance, and excellent mechanical properties, this steel alloy, similar to its counterparts 17 4 PH and AISI 630, features a composition comprising approximately 15% chromium, 4% copper, 5% nickel, along with trace amounts of manganese and silicon.

Storage in the H1100 and H1150 states enables use in the low temperature range. Excellent notched impact strength is also given at sub-zero temperatures. Due to its corrosion resistance and good mechanical properties, 15-5 PH XM-12 steel is suitable for use in maritime environments. In stagnant seawater, rectangle bar 15-5 PH is susceptible to stress corrosion cracking but insensitive to intergranular corrosion.

International identifiers of 15-5 stainless steel:

AISI XM-12, ASTM A564-89 15-5PH, UNS S15500

Applications of stainless steel 15-5 PH:

15-5 PH is used in mechanical and plant engineering, in the chemical, paper and wood industries. Other areas of application include medical technology, the oil industry, shipbuilding, the offshore, aviation and marine sectors. aerospace and in the sports and leisure industry.

Characteristics of steel 15-5 PH:

| forgeability: | good |

| machinability: | 3 (1 = bad- 10 = good) |

| polishing: | yes |

| corrosion class: | 0 – 5 3 (0 = weak – 5 = good) |

| corrosion resistance: | good |

| mechanical properties: | excellent |

The distinctive traits of 15 5 steel XM-12 include its outstanding suitability for low temperatures, serviceability at temperatures up to approximately 315°C, remarkable strength, and toughness. Furthermore, it can undergo age-hardening, and its strength can be further enhanced through cold forming with subsequent aging.

Forging : Forging of 15-5PH stainless steel occurs within a temperature range from 1180°C to 950°C, with cooling to room temperature taking place in the surrounding air.

Welding: Optimal welding conditions are imperative, taking into account the stable presence of copper in the base material. To prevent stress cracking, the material must undergo solution annealing shortly after welding, followed by aging.

Corrosion resistance: 15-5 stainless steel, or AISI 630, is suitable for deployment in marine environments, exhibiting excellent mechanical properties and corrosion resistance. Additional protective measures are necessary against crevice corrosion induced by stagnant seawater.

Machining: 15-5PH is machinable in both the age-hardened and solution-annealed conditions, with machinability varying depending on the hardness state.

Chemical analysis of 15-5 PH stainless steel:

| 15-5 PH | C | Si | Mn | P | S | Cr | Mo | Ni | V |

| min. | 14,00 | 3,50 | |||||||

| max. | 0,07 | 0,7 | 1,0 | 0,030 | 0,015 | 15,50 | 0,50 | 5,50 |

| 15-5 PH | Al | Cu | N | Nb | Ti |

| min. | 2,50 | 5xC | |||

| max. | 4,50 | 0,45 |

15-5 ph:

flat steel, forging

Produced to highest standards

Quick delivery

From stock in Europe