316 ss steel

ANY SIZE – ANY TIME

Your specialist for AISI 316/ SS 316L from forged billets. We provide metal cutting services.

The annealed chromium-nickel-molybdenum steel AISI 316 / AISI 316 L is a stainless, austenitic steel with low carbon content. Due to the addition of 2 – 2.5% molybdenum, the corrosion resistance of AISI 316 / AISI 316 L is significantly better compared to standard austenitic steels.

AISI 316 L stainless steel is resistant to intergranular corrosion in the welded condition! No resistance to sea water! With polished surface the best corrosion resistance is given. Our rectangle bars 316 SS are widely used in the construction, automotive, and manufacturing industries.

International identifiers of 316 ss steel:

SS 2343, SS 2348, SS 2553, ASTM 316L, UNS S31603, AFNOR Z2CND17-12, BS 316S12, UNI X2CrNiMo1712, JIS SUS316L, GOST 03Ch17N13M2, GB 022Cr17Ni12Mo2, 1.4404

Applications of ss 316 stainless steel:

Aisi 316 is mainly used in automotive industry, chemical industry, construction industry, petroleum industry, petrochemical industry, engineering, decorative and kitchen equipment, food industry, aviation, electronic equipment, medical and pharmaceutical industry.

Properties of stainless steel 316 ss:

| welding qualification | medium |

| mechanization | 6 (1 = bad – 10 = very good) |

| polishing | yes |

| corrosion resistance | low |

| corrosion class: | 4 ( 0 = bad – 5 = good) |

Forging: During the forging process, slow heating to approx. 1150°C – 1180°C takes place in order to forge in a temperature range of 900°C – 1180°C. Subsequently, air or water cooling takes place. A reduction in corrosion resistance is achieved by scale or tarnish.

Welding: AISI 316 / AISI 316 L stainless steel can be welded well with and without filler metal. An interpass temperature of 200°C should not be exceeded. No heat treatment is required afterwards. The resistance to intergranular corrosion is not affected by the heat input during welding.

Corrosion resistance: Due to its low carbon content, AISI 316 / AISI 316 L is resistant to intergranular corrosion, but is not resistant to seawater. Excellent corrosion resistance is given in natural environmental media and moderate chlorine and salt concentrations.

Cold forming: AISI 316 / AISI 316 L is suitable for cold forging

tratamiento térmico

| Temperature in °C | Cooling | |

| Hot forming | 1.200 – 900 | air, water |

| Heat treatment | ||

| Solution annealing (+AT) | 1020-1120 | water, air |

Processing:

| cold forming | is possible |

| Spent processing | is possible |

| Free-form and drop forging | is possible |

| Cold diving | is possible |

Physical Properties AISI 316:

| Density in kg/dm3 | 8,0 |

| Electr. Resistance at 20°C (Ω mm2 /m) | 0,75 |

| Thermal conductivity at 20°C in W/(m K) | 15 |

| Specific heat capacity at 20°C (J/kg K) | 500 |

Chemical analysis of stainless steel ss 316:

| AISI 316 SS 316L |

C | Si | Mn | P | S | Cr | Mo | Ni | Cu | N |

| min. | 16,50 | 2,0 | 10,0 | |||||||

| max. | 0,030 | 1,0 | 2,0 | 0,045 | 0,,30 | 18,50 | 3,0 | 14,0 | 0,30 | 0,10 |

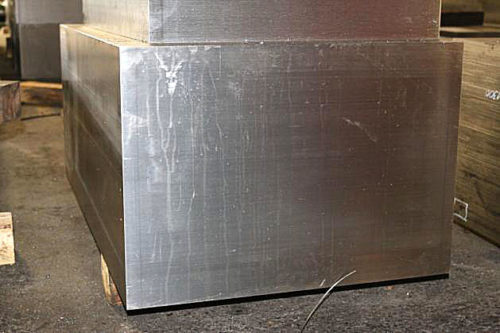

AISI 316:

AISI 316 Flat, forged

Benefits of sawn cuts from 316 ss steel:

Due to mechanical processing with the saw, the material structure shows much lower unintentional deformation and material hardening than, for example, oxyfuel cutting. Therefore, the already machined piece from the saw has a homogeneous structure at the edge, which remains unchanged in the further processing of the material. This circumstance allows for immediate finishing work with milling or drilling of the piece, without the need for additional annealing or similar processes.

Produced to highest standards

Quick delivery

From stock in Europe

Popular steel: