630 stainless steel / ss 630 / 1.4542

ANY SIZE – ANY TIME

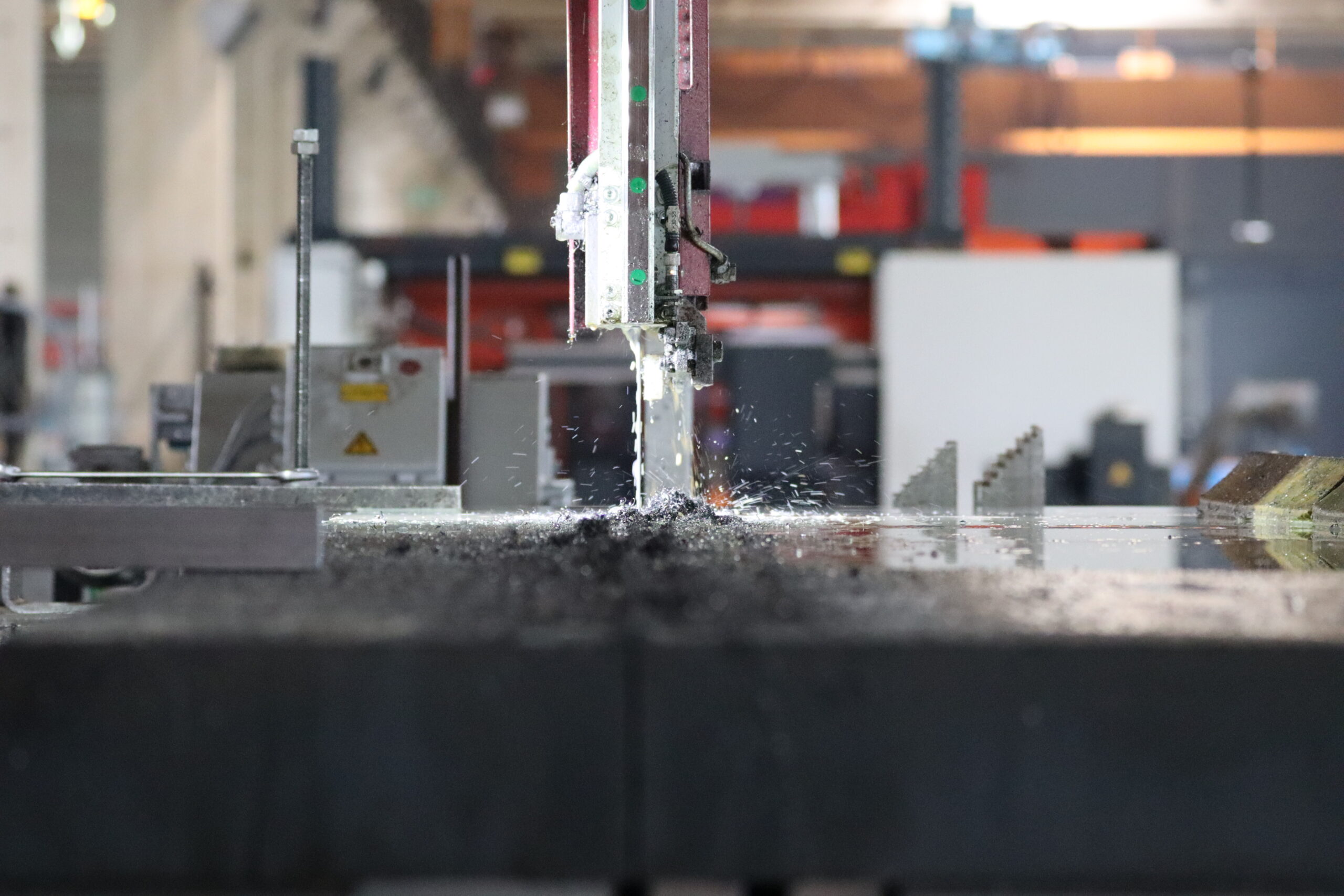

Your specialist for AISI 630 sawn steel from forged billets directly from stock in Texas. We provide metal cutting services.

SS 630, contains approximately 17.5% chromium, 5% copper, and additional nickel, molybdenum, and other elements.

The maximum carbon content is 0.07%. It is analytically the same with the materials 17-4 ph.

AISI 630 is a martensitic, hardenable, stainless steel with high wear resistance, good corrosion resistance and high yield strength.

International appellations of 630 stainless steel:

ASTM A564-89 17-4PH, JIS SCS24 / SUS630, AFNOR Z7CNU15-05 / Z7CNU17-04, 1.4542, 1.4548

Applications of ss 630:

The combination of excellent mechanical properties and high corrosion resistance allows AISI 630 to be used in maritime environments, although it is susceptible to stress corrosion cracking in stagnant seawater. Notched impact strength is excellent at sub-zero temperatures.

Rectangle bar SS630 is machinable both in the solution-annealed and hardened condition, whereby the machinability depends on the hardness. SS 630 is used in the aerospace, chemical, petrochemical and petroleum industries, in medical and dental technology, in plant construction and in shipbuilding. 630 ss for oil and gas industry.

Properties of AISI 630 material:

Characteristics: This steel alloy exhibits special properties such as suitability for low temperatures and operation up to approximately 315 °C. Notable for its high strength, toughness, and age-hardenable capability, the steel allows strength enhancement through cold forming with subsequent aging.

Forging: Forging of AISI 630 stainless steel occurs in a temperature range from 1180°C to 950°C, with cooling to room temperature taking place in the surrounding air.

Welding: Optimal welding conditions are essential, considering the stable presence of copper. To prevent stress cracking, the material must undergo solution annealing shortly after welding, followed by aging.

Corrosion resistance: SS 630 is suitable for use in marine environments, showcasing excellent mechanical properties and corrosion resistance. However, additional protection is needed against crevice corrosion caused by standing seawater.

Maching: AISI 630 is machinable in both the age-hardened and solution-annealed conditions, with machinability varying depending on the hardness state.

Chemical analysis of 630 ss material:

| AISI 630 | C | Si | Mn | P | S | Cr | Mo | Ni | V |

| min. | 15 | 3 | |||||||

| max. | 0,07 | 0,7 | 1,0 | 0,04 | 0,03 | 17,50 | 0,6 | 5 |

AISI 630 directly from stock:

flat, forged

Benefits of sawn cuts of 630 stainless steel:

Due to the mechanical processing with the saw, the structure of the material shows much less unintentional deformation and material hardening than, for example, oxyfuel cutting.

Therefore, the workpiece already machined by the saw has a homogeneous structure at the edge, which does not change in the material continuation.

Produced to highest standards

Quick delivery

From stock in Texas

Specialist for sawn steel blocks directly from stock USA

Karol Borycki