F6NM material / ASTM A182

ANY SIZE – ANY TIME

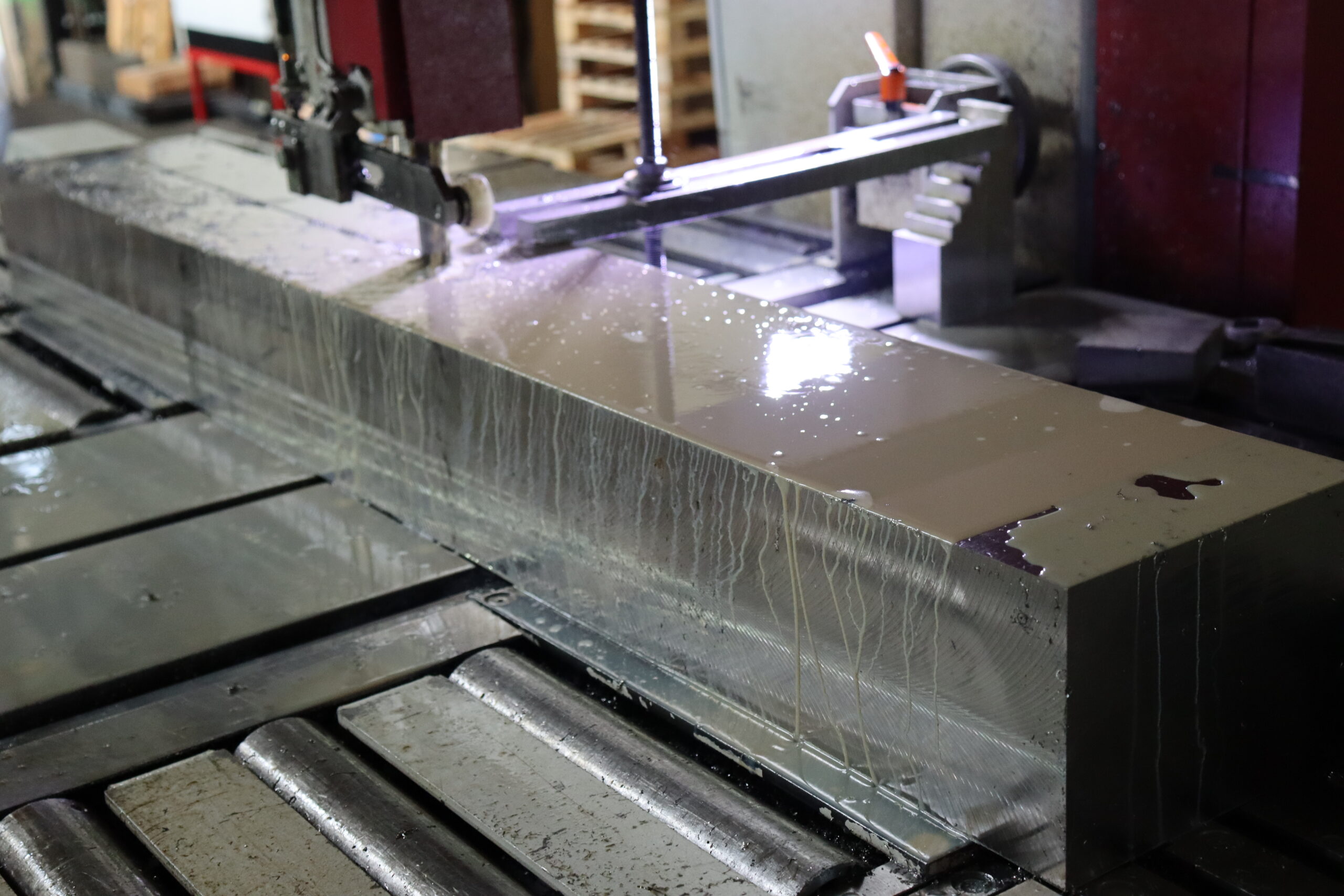

Your specialist for ASTM A182 F6NM sawn steel from forged billets. We provide metal cutting services.

F6NM martensitic chromium-nickel steel is rust and acid resistant with molybdenum addition. It has medium corrosion resistance. The ever-increasing demand for F6NM is due to its good toughness properties and the resulting versatile performance range. The soft-martensitic and stainless steel is used for valves, compressors or centrifuges. Our rectangle bars F6NM offer excellent strength and corrosion resistance, making them ideal for demanding environments.

International identifiers F6NM:

F6NM / C54868 / S41500 / SGS6X / SGS5 / ASTMA182 / F6NM430F

Applications of F6NM material:

F6NM ss material is used in the petroleum industry, in the manufacture of turbine runners for hydroelectric power plants, and for components in power plant and reactor construction.

Properties of F6NM stainless steel:

| Machinability: | 5 (1 =bad- 10 = good) |

| Welding suitability: | bad |

| Polished: | yes |

| Corrosion class: | 2 (0 = weak – 5 = good) |

Chemical composition of F6NM steel:

| ASTM A 182 F6NM | C | Si | Mn | P | S | Cr | Mo | Ni | V | Al | Cu | N | Nb | Ti |

| min. | 12,00 | 0,4 | 3,5 | 0,02 | ||||||||||

| max. | 0,50 | 0,60 | 1,0 | 0,035 | 0,02 | 14,00 | 0,7 | 4,5 |

F6NM:

flat, forging

Benefits of sawn cuts of F6NM material:

The use of a saw for processing involves mechanical manipulation of the material, resulting in a reduced risk of unintended deformation and increased hardness compared to thermal cutting methods. As a result, the workpiece maintains a consistent structure, allowing for seamless continuation of material processing. This characteristic enables immediate finishing touches through milling or drilling without the need for pre-annealing or similar procedures.

Produced to highest standards

Quick delivery

From stock in Europe

Our expert knowledge about F6NM material

What is the tensile strength of F6NM?

The tensile strength can vary from 650 MPa to over 1100 MPa depending on the property state.

At what temperature can F NM be hardened?

F6NM is annealed within the temperature range of 950°C to 1050°C and then hardened by rapid cooling using air, oil, polymer, or water.

Is F6NM magnetic?

F6NM is a ferromagnetic material.

How can F6NM be hardened and tempered?

The process involves first hardening F6NM to a martensitic structure and then tempering at temperatures above 500°C.

Is F6NM corrosion resistance?

While F6NM is corrosion-resistant, it can still rust under certain environmental conditions.

What ist he density of F6NM?

The density of 1.4313 ranges from 7.70 to 7.85 kg/cm³, depending on its precise composition.

What ist he Machinability of F6NM?

The machinability varies with the hardness level, but it can generally be considered good compared to other high-alloy steels.