SS 410 stainless steel – AISI 410

ANY SIZE – ANY TIME

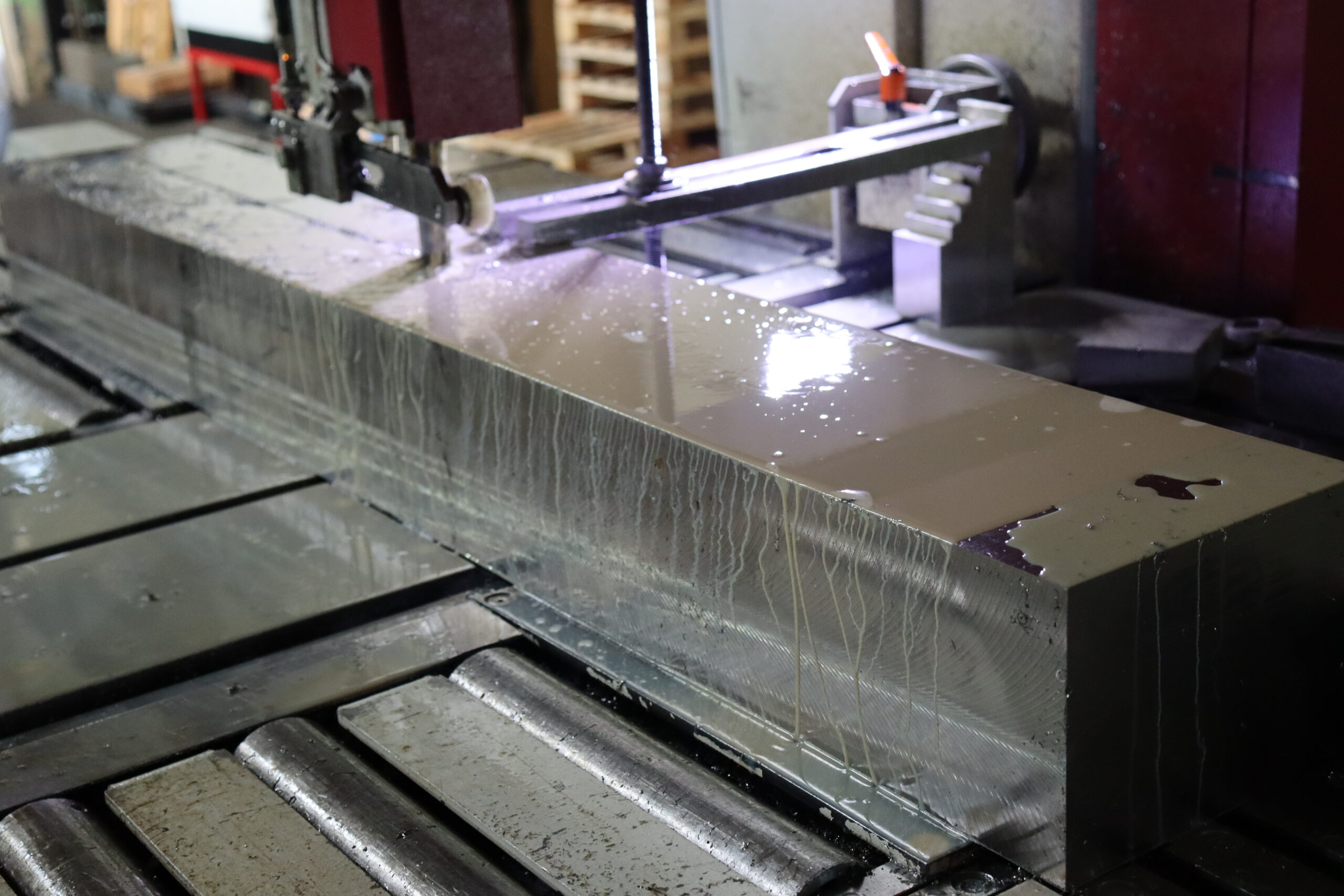

Your specialist for SS 410 sawn steel from forged billets. We provide metal cutting services.

The stainless steel AISI 410 has undergone a special heat treatment. It is supplied hardened and tempered and double-hardened and therefore complies with the NACE standard. Aisi 410 is a stainless steel with good corrosion resistance in moderately aggressive, chloride-free media such as organic acids, soaps and solvents. Polishing of the surface is required for optimum corrosion resistance.

It is a stainless and martensitic stainless steel. The chromium content of SS 410 is 11.5 – 13.5%. Special properties, such as a low susceptibility to embrittlement, the possibility of mirror polishing and the application range up to 400°C characterise the SS410 material. We manufacture our rectangle bars 410 with the highest standards, ensuring consistent quality.

International identifiers of ss 410 steel:

AISI 410, BS 410S21, AFNOR Z10C13, SS 2302, UNS S41000, AFNOR Z13C13, UNI X12Cr13, GOST 12Ch13, 1.4006

Applications of 410 stainless steel:

AISI 410 steel is mainly used in mechanical engineering, the oil industry and the petrochemical industry.

Mainly AISI 410 steel is used in mechanical engineering, petroleum and petrochemical industries.

Weldability of aisi 410 ss:

| Welding: | well |

| Mechanization: | 5 (1 = bad – 10 = good) |

| Polishing: | yes |

| Chorosion class: | 1 (0 =weak- 5 = good) |

Chemical composition of material 410 ss:

| SS 410 Aisi 410 |

C | Si | Mn | P | S | Cr | Mo | Ni | V |

| min. | 0,08 | 11,5 | |||||||

| max. | 0,15 | 1,00 | 1,50 | 0,04 | 0,02 | 13,5 | 0,75 |

Weldability of 410 stainless steel

Resistance to corrosion is highest with a polished, smooth surface. This stainless steel can be highly polished. Due to its very good welding properties, various welding processes can be used with material SS 410:

TIG welding, MAG welding, arc welding and laser beam welding. Resistance welding, on the other hand, is only feasible to a limited extent.

Benefits of sawn cuts from 410 ss material:

Due to the mechanical processing with the saw, the structure of the material shows much less unintentional deformation and material hardening than, for example, oxyfuel cutting.

Therefore, the workpiece already machined by the saw has a homogeneous structure at the edge, which does not change in the material continuation.

This circumstance allows the workpiece to be finished immediately by milling or drilling, there is no need for soft annealing or similar.

AISI 410:

Flat steel, forged

Produced to highest standards

Quick delivery

From stock in Europe

Our expert knowledge about ss 410 stainless steel

What ist stainless steel 410?

Stainless steel 410 is a type of martensitic stainless steel alloy. It’s primarily composed of iron, with around 11.5-13.5% chromium content. Additionally, it may contain small amounts of carbon, manganese, silicon, phosphorus, sulfur, and other elements.

Is AISI 410 resistant to seawater?

AISI 410 is resistant to seawater. Its corrosion resistance makes it suitable for use in marine environments, where it can withstand exposure to saltwater.

Is AISI 410 stainless steel magnetic?

AISI 410 stainless steel is indeed magnetic. This magnetic property is primarily attributed to its microstructure, which consists mainly of martensite, a type of crystalline structure that typically exhibits ferromagnetism.

Martensitic stainless steels like AISI 410 undergo a process called martensitic transformation during heat treatment, where austenite transforms into martensite, resulting in a hardened material with improved strength and hardness. This transformation contributes to the magnetic nature of AISI 410.

The magnetic properties of AISI 410 make it suitable for various applications where magnetic characteristics are required or preferred, such as in components for magnetic assemblies, magnetic sensors, and magnetic separation equipment.

What ist the weldability of SS 410?

The weldability of SS 410 can be challenging. While it can be welded using conventional methods, preheating and post-weld heat treatment are often required to minimize the risk of cracking and ensure satisfactory results.

What is special about AISI 410 material?

Our AISI 410 stainless steel undergoes a specialized heat treatment process, by quenching and tempering and double tempering, it thus complies to the rigorous NACE standards.